Same Language, Different Dialects: Analyzing Plant Performance Around the Globe

Manufacturing

D&A Solutions

Now that all our plants across the globe use the same metrics, we’ve gotten much better at finding ways to help each other improve plant performance, which has helped the company as a whole.

Senior Director, Global Manufacturing Operations

Meeting the Challenge

How can a Finance team unify metrics across global manufacturing sites?

The Finance team at our client, a major supplier of finished goods for automotive, struggled to get a single review of important financial metrics across its global manufacturing plants. While all plants used SAP, each plant applied its own customizations, using different GL accounts and segments to store financials, and applying unique reference data for its operations.

It was as if each plant spoke a different language, making it difficult to compare and evaluate performance across the globe.

Comparison and evaluation of manufacturing performance across plants is essential for long-term strategic planning and improving operational efficiencies, reducing costs, and rationalizing plant retention. But without a standard definition of key metrics, such analysis was extremely difficult.

Our Solution

Creating a common language for analysis and collaboration

To overcome these challenges, Axis built a mapping solution that intelligently fit the data from each plant into a common standard. With this mapping, the company’s Finance leadership was finally able to get a uniform view of key metrics, such as inventory turns and net sales. Perhaps more importantly, a uniform view gave them a common language for analysis across all their plants, allowing new opportunities for plant personnel to collaborate, share best practices and identify areas for improvement. Perhaps one plant was effective with inventory turns, but not as strong with inventory management, while another plant was in the reverse situation; our solution gave managers a way to share ideas and improve operations, since now they could speak the same language.

Our solution allowed the company’s Automotive team to understand and compare global plant performance in a single view, with the ability to drill down into further details and explain variances. It lets them understand individual plant performance relative to overall global performance, and tactically target metric and plant deficiencies for improved focus and efforts.

And the KPI solution has already had a real impact on operations. In 2022, for example, the company was able to use the new solution to drastically reduce premium freight charges. Now that all the plants are “speaking the same language”, they can expect to find more ways to optimize operations and reduce costs.

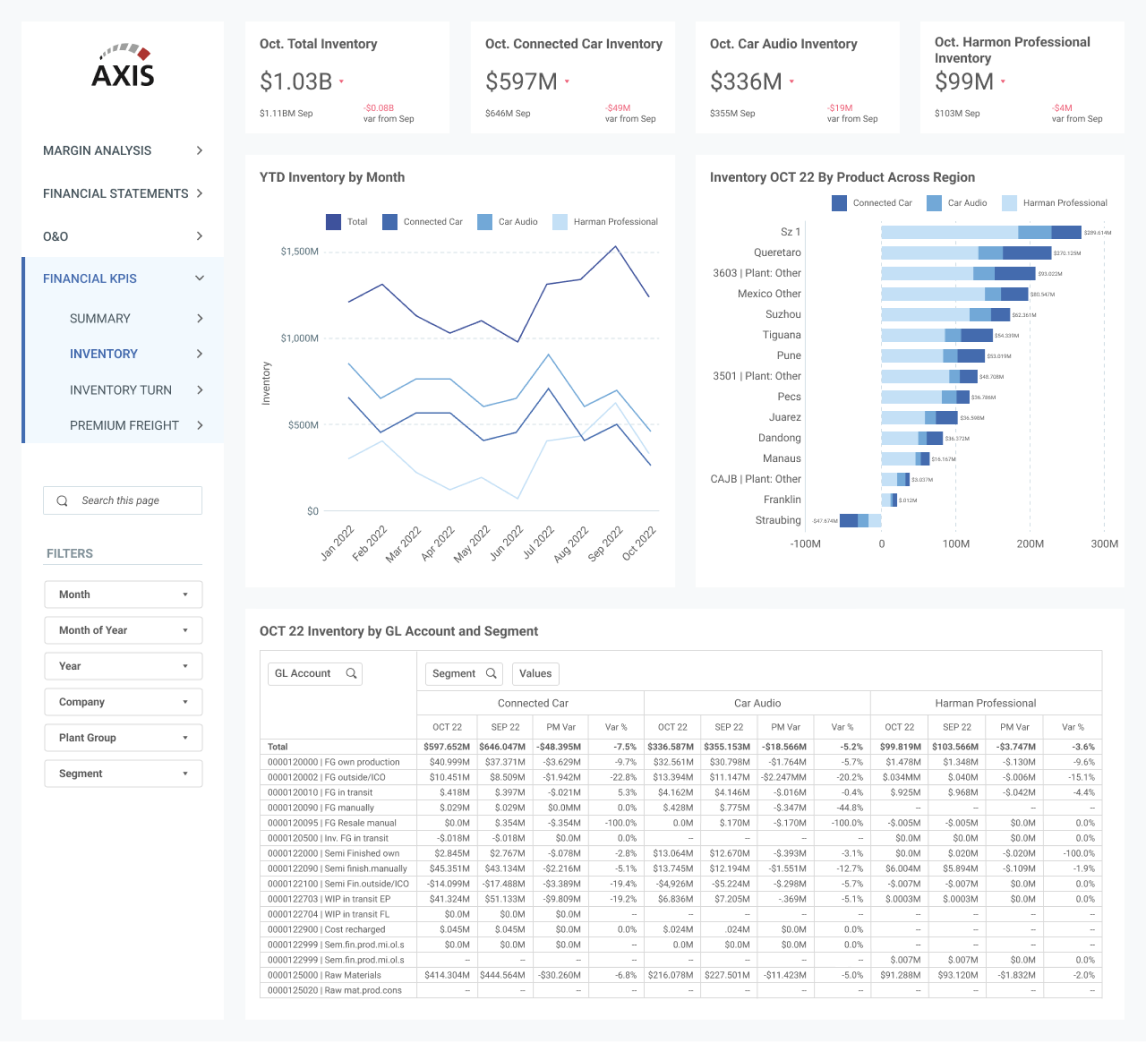

Solution Sample: By combining aggregate P&L data with low-level transactions, Finance leadership can more quickly analyze changes to profitability and identify the drivers that need attention.

Are you ready to take the next step on your Data & Analytics journey?