Supplier Scorecard Puts Procurement Firmly in the Driver’s Seat

Manufacturing

D&A Solutions

Our customer was finally able to generate the objective supplier metrics they need to evaluate performance, head off quality issues, and build trust with their vendors. What was a manual, once-a-year process is now automatic and continuous.

Richard Villanti, Axis Group

Meeting the Challenge

How can a company objectively evaluate and improve its suppliers’ performance?

Supplier scorecards have become an important way for businesses to manage their vendor performance, uncover supply chain issues and foster collaboration with their suppliers. Since they break down vendor performance into concise, quantifiable criteria, supplier scorecards are an effective way to assess and compare providers on an apples-to-apples basis. Scorecards have become an essential tool to communicate expectations, mitigate supplier risk and promote successful partnerships.

For a company like our client, a Fortune 500 consumer electronics manufacturer, the supplier scorecard process was a real struggle. With hundreds of finished products composed of tens of thousands of components from a complex web of nearly 1,000 global suppliers, it was critical for them to measure performance using objective criteria.

Yet they faced significant challenges to building scorecards—an annual process that required weeks of work to produce them for even a few suppliers. Since the data required to build a 360 degree view of a supplier resided in a number of different sources, even assembling the data was difficult. Component cost and on-time delivery data was in SAP; component quality and defect reports were in their own system; and core supplier data interchange capabilities resided in Ariba. Each source required a different team to query data and create reports, and deliver the raw data to the supply chain team. From there, the supply chain team faced the challenge of manipulating the data using spreadsheets without introducing errors.

And even after weeks of effort, the end product was of limited utility. Many important data points were not included; only a few dozen suppliers were scored; and the information was often out of date by the time the team was able to deliver scorecards to suppliers.

But perhaps most importantly, without universal and timely supplier scores across the board, it was difficult for teams to manage and improve vendor quality, cost or performance.

Our Solution

Axis designed a Supplier Scorecard that objectively quantifies vendor performance and helped our customer build trust with its suppliers.

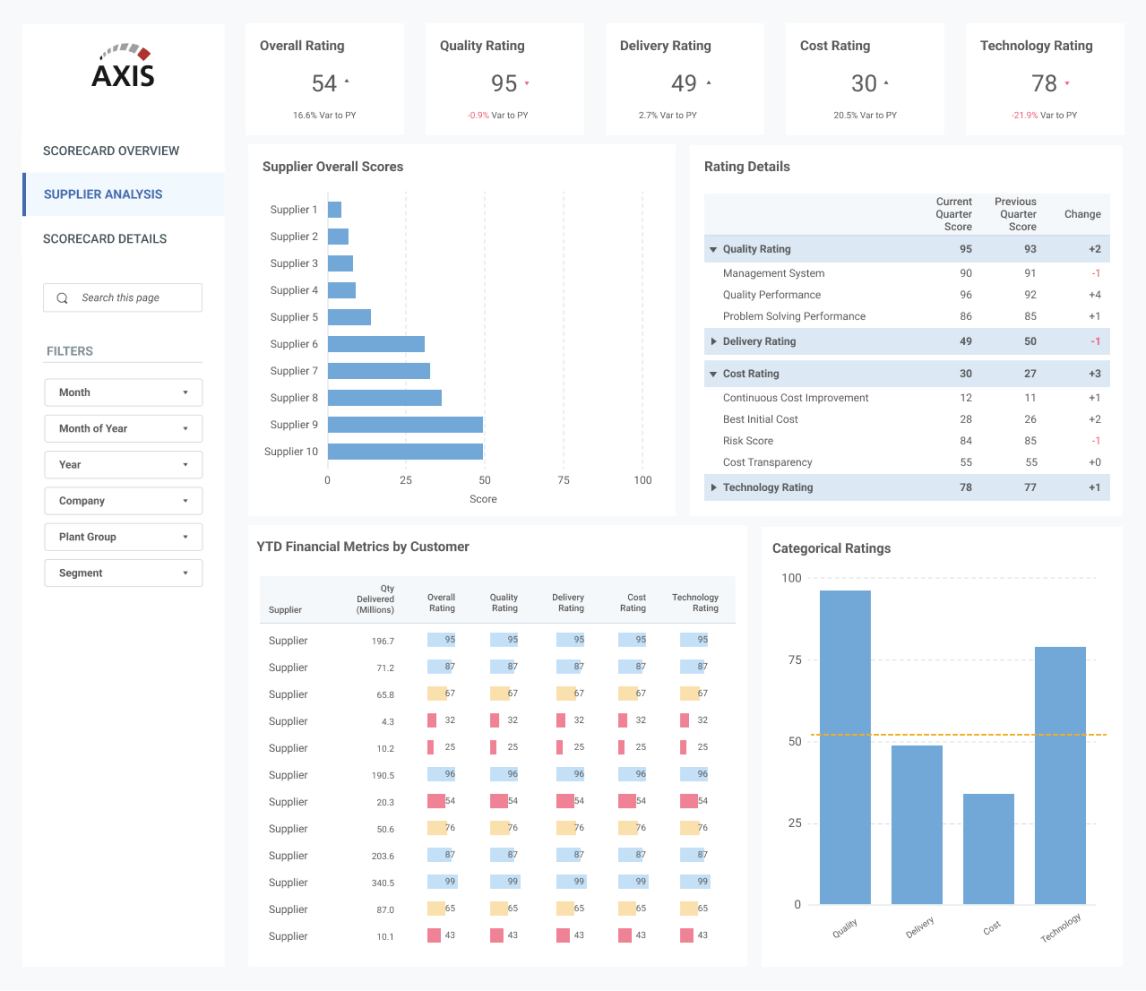

That’s when our client turned to Axis. We used our Solution Design Methodology to design objective benchmarks and KPIs that reflect all the real-world decisions the supply chain team needed to make about vendor quality, cost, timeliness and performance. After several design iterations, we constructed data pipelines and a front-end application and tested it with users to make sure it met their needs.

The company now automatically sends out quarterly vendor scorecards across the board, can quickly compare historical figures, and manages vendor performance with objectivity and transparency. Category managers are having more informed performance conversations, and improving outcomes with better performance data—without needing to spend weeks assembling data.

In short, the Axis supplier scorecard has changed how our client works with its vendors to communicate expectations and is building more trusted relationships with its suppliers.

Now, the company can answer all these questions quickly and reliably:

- How reliable is a particular supplier in terms of meeting delivery deadlines and producing goods of the required quality?

- How competitive is a supplier's pricing, and how does it compare to other suppliers?

- How responsive is a supplier to requests for information or assistance?

- How sustainable are a supplier's business practices, and how do they align with the company's own sustainability goals?

- What opportunities for cost savings or process improvements exist in the relationship between the company and a particular supplier?

Solution Sample: We designed objective Supplier benchmarks and KPIs that help the Supply Chain team make real-world decisions, such as vendor quality, cost, timeliness and performance.